Improve Health

Made in the USA of the Highest QualityDual Density Poly-fiber filter cloth. Rated at 93-97% efficiency by Air Filter Testing Lab, Inc. Crestwood, Kentucky. Central Texas Filters Guard against Bacteria, Debris, Dust/Lint, Dust Mites, Microscopic Allergens, Mold, Oil Smoke, Pet Dander, Pollen, Smog, Smoke, and Virus Carriers.

Do Your Pocketbook a Favor

More than one third of your cardboard filter surface (those crisscrossing fingers of cardboard on the face of your filter) redirects or impedes the air from going through your air conditioning or heating system. This, in time, can cause problems by putting strain on the motor or motor drag, which ultimately could lead to motor repair. It could also overheat the wiring system and crystallize the insulation which could ultimately require new wiring!

Pleated Filters VS Dual Density Poly-Fiber Filters Our Winner is --- Dual Density Poly-Fiber

Key Measures to Understand:

Initial (clean Filter) pressure drop --- the lower the better

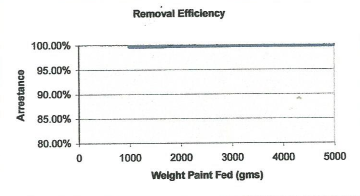

Dust arrestance – the higher the better

Final pressure drop (dirty, or loaded, filter) – the lower the better

Our Dual Density Poly Fiber filters and Pleated filters take different approaches toward the same goal of protecting HVAC systems and the environments they supply.

Our Poly-Fiber is a type of “contact” filter, promoting a better chance of particles being trapped due to media depth for a given density. By using two different densities for a given depth, that introduce an electrostatic charge no matter of depth or density, decreases fiber size –(better for smaller particles) and/or other combinations arrestance efficiency is increased. By trapping these particles, without a significant drop in pressure you can enjoy Fresh Healthy Air year round.

Pleats are classified as “extended surface area” filters due to their construction. The filter media itself is thin and dense. The density increases the likelihood that a given particle will be trapped by the filter and results in a higher maximum potential efficiency (MERV). Unfortunately, the density also increases the filter’s resistance to the air flow. This resistance causes a pressure drop and reduction of air flow downstream from the filter bank. So, the extended surface filters compensate for this disadvantage by “PLEATING” the media in order to increase the surface area exposed to the air flow and makes a more acceptable resistance. This is primarily effective in the large industrial HVAC units rather than the smaller home systems.

We believe our polyester media is the right choice:

Dual Density – large and small fibers for arrestance efficiency across a broad range of particle sizes

Passive Electrostatic – media is continually charged by the flow of air, attracts particles of all sizes by static charge

Lower initial pressure drop – lower resistance to air flow than pleats for same application

High dust arrestance – matches pleated performance

Lower final pressure drop – lower resistance to air flow as filter gets dirty

YOU SAVE MONEY –Lower resistance (pressure drop) means you save on energy bills short term and repair bills long term.

* References: NAFA Guide to Air Filtration/Air Filter Testing Laboratories, Inc.

Contact Us

Contact Us now to schedule an appointment or order a Home Kit!